In the flourish era of clean energy, hydrogen parts manufacturing stands as a critical pillar. Meanwhile, it’s challenging to make sure that components fulfill strict safety and quality requirements. This is where high nickel machining specialists shine – bridging precision engineering with robust safety standards to deliver parts engineered for hydrogen applications.

Why Safety Standards Matter for Hydrogen Components

Hydrogen is an incredibly promising energy vector, but its flammability and potential for embrittlement demand meticulous attention. Safe parts must adhere to rigorous frameworks – such as NFPA 2 (Hydrogen Technologies Code), ISO 14687, ISO 19880, ATEX, and PED – that govern design, materials, testing, and certification.

Compliance isn’t optional – it’s essential. From storage vessels to fuel system components, every part must resist hydrogen embrittlement, endure high pressure, and function flawlessly in extreme conditions.

The Nexus of High Nickel Machining & Hydrogen Safety

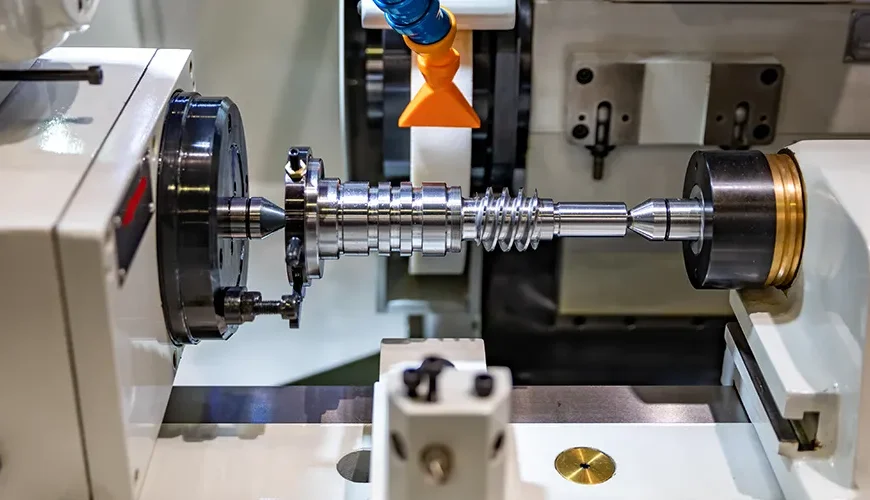

Nickel alloys are prized for their corrosion resistance, high-temperature performance, and strength – qualities that align perfectly with the demands of hydrogen environments. When machined by true high nickel machining specialists, these materials become reliable components that meet both mechanical and safety standards.

Machining nickel alloys involves unique challenges – intense heat, work-hardening, and tool wear – but when expert specialists manage these variables, the result is precision-engineered parts that stand up to safety codes and real-world demands.

Key Quality Requirements in Hydrogen Parts Manufacturing

1) Material Compatibility & Certification:

Parts must be constructed from materials tested and qualified for hydrogen service, including assessments for embrittlement resistance according to ASTM or ISO standards.

2) Structural Integrity & Pressure Compliance:

Tanks and components must adhere to ASME Boiler & Pressure Vessel Code (Section VIII) or PED, ensuring they withstand the rigors of high-pressure hydrogen environments.

3) Process Safety & Traceability:

Manufacturing workflows must align with global safety codes and standards (such as ISO 14687, ISO 19880, ATEX, and PED) to facilitate certification and traceable quality control.

4) Surface Finish & Dimensional Precision:

Even minute surface flaws can become failure points under hydrogen exposure. High nickel machining specialists deliver parts with flawless surface finishes and tight tolerances to prevent leakage and ensure operational safety.

5) Testing, Inspection & Documentation:

Rigorous nondestructive testing, pressure validation, and embrittlement analytics must accompany every batch. Full documentation – including material certificates and QA reports – supports verification and compliance.

Final Thoughts

In hydrogen parts manufacturing, safety is the foundation upon which every part must stand. That’s why partnering with high nickel machining specialists isn’t a luxury – it’s a necessity. With expert craftsmanship, deep material knowledge, and unwavering compliance, these specialists deliver components that power the future – safely and reliably.

At Mentco, we embrace the high precision and discipline required for hydrogen parts – combining expert high nickel machining with rigorous safety and quality protocols. Ready to elevate your hydrogen projects with superior components? Reach out to Mentco today – where safe, high-performance manufacturing meets unwavering integrity.

Frequently Asked Questions (FAQs)

Q1. What makes nickel alloys especially suitable for hydrogen parts?

Nickel alloys excel due to their corrosion resistance, temperature stability, and mechanical strength-making them ideal for pressurized hydrogen service where reliability and safety are paramount.

Q2. How do safety codes like NFPA 2 and ISO standards affect manufacturing?

These codes mandate strict requirements around design, materials, testing, and certification for hydrogen-related components. Adherence lowers the chance of catastrophic failure and guarantees legal compliance.

Q3. What precautions are needed to prevent hydrogen embrittlement?

Manufacturers employ qualified nickel alloys, follow embrittlement testing protocols (e.g., ASTM or ISO methods), and apply precise machining and heat treatments to mitigate vulnerability.

Q4. Why is tight dimensional control critical in hydrogen components?

Hydrogen’s tiny molecular size can exploit even the smallest gaps. High-accuracy machining minimizes leak paths and supports durability in demanding operating conditions.